April 22, 2025

Leading by Example: Sustainable Growth in La Crosse

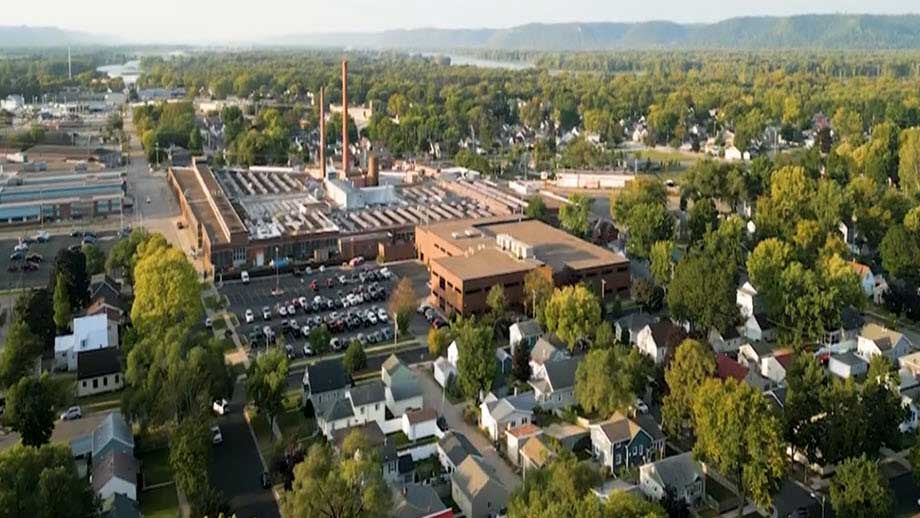

Our La Crosse facility, where Trane® was founded more than 100 years ago, is helping lead our business toward a more sustainable future.

We’re leading by example through responsible operations, reimagining our systems and taking action to have a restorative impact on the environment.

Project At-a-Glance:

The opportunity for La Crosse

As capacity for data centers continues to grow, so does demand for our sustainable technology. At our manufacturing center in La Crosse, Wisconsin, we are meeting customer demand for high-efficiency chillers while reducing the environmental impact of our operations. The challenge: grow sustainably.

The solutions:

- Build a new, highly automated manufacturing line to expand capacity for our electrified solutions, including the CDHH CenTraVac® water-cooled chillers, the largest heat recovery unit we have ever made

- Secure a five-year power purchase agreement to procure electricity from 100% renewable sources for our operations

- Implement a strategy to achieve zero waste to landfill

- Streamline operations to reduce water usage and emissions, including the installation of a cooling tower and our own thermal battery storage source heat pump system

- Continue to invest in our industry-leading Graduate Training Program to educate best-in-class technical sales force and energy engineers

- Build culture through employee volunteerism, especially in STEM and environmental stewardship

Sustainability outcomes:

- Supporting customers in high-growth sectors, including data centers and semiconductor manufacturing, in meeting demand and achieving their decarbonization goals

- Achieved zero-waste-to-landfill as of November 2022

- Contributed significantly to Trane Technologies’ water use reduction of 20 percent in 2023:

- Thermal storage system in training center building saved 15 million gallons of water in 2023 compared to 2022—a reduction of 85%. Expected reduction of 30-40 million gallons of water and 21 mtCO2e annually. Expected reduction of overall energy intensity of the training center building by 28%.

- Facility’s electricity 100% generated from renewable sources as of October 2024

- Graduate the best trained technical sales leaders and decarbonization champions in the industry each year through the Graduate Training Program

- 8,832 hours volunteered by employees in the La Crosse community in 2024

Watch the video to learn more about sustainable growth in La Crosse

Trane La Crosse is a special place. It's a hidden gem to have the world's leading HVAC company in a town of 50,000 people. And we're sitting in our technology building today, that's got a leading HVAC laboratory, some of the best engineers in the world, not only in the HVAC industry, but they're surrounded by a community.

La Crosse was given a gift and it was the gift of volume and so many customers want our chillers. They want sustainability. A lot of the customers come to Trane with requests that nobody else can do. And we can do it because we have the team that can make it happen.

When we talk about decarbonizing, we are really talking about utilizing electric equipment as opposed to gas fired equipment that's going to create emissions. We have the opportunity with water cooled chillers to take that heat and use it in a building. The ability to optimize energy efficiency and redesign systems so that we can utilize electric means of heating and cooling, are one of the major impacts that we have across the united states and in future designs.

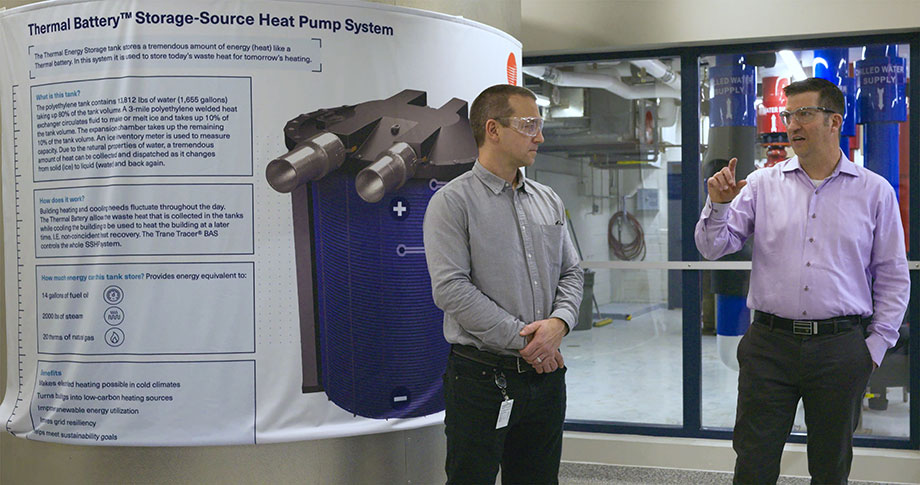

We are a technology company that heats and cools buildings. So one of the first projects that our laboratory team did was to develop a closed loop solution for some of our facilities. Really significantly reduced the water consumption of La Crosse. The other one that I'm really excited about is the thermal management system that we put into our new training center in building 13. So this is a completely new HVAC system that got us definitely outside of our comfort zone. So, it’s a fully electrified system that we're able to do both heating and cooling in a very cold climate.

Leading by example, we focused on the zero waste to landfill initiative. As well as reducing emissions by engaging in a five-year contract for renewable sources. Trane La Crosse is 100% powered by renewable energy.

If we think about our innovation in our company, we think about our goals around sustainability. Our people are really the connecting point between our innovation and those sustainable solutions. The Graduate Training Program continues to be a differentiator for Trane Technologies. It is the largest investment of anybody in the industry. This program is nearly 100 years old now. We recruit the best of the best, put them through the most comprehensive training program, and send them out there to serve customers. We're living our best business right now, in terms of the talent we've brought in the organization, in terms of how that talent works together, in terms of how we're aligned to achieve sustainability goals that we've never achieved before. That's what our culture feels like today.

It's my job and our job as leaders to develop this team and keep them growing so Trane is around for the next 112 years, because that's the organization. That's who we are.

Teams can be successful, but families win championships. And that's what we have here. A father, a son and a daughter started a heating business. And it's been here for over a century. We're poised to make sure it's here for the next century.

Sustainability is our strategy—in La Crosse and all across Trane Technologies. Our growth is directly linked to our bold 2030 Sustainability Commitments to significantly reduce carbon emissions for our customers, to reduce our own environmental impact and to uplift people and communities by creating opportunities for all.

Our La Crosse, Wisconsin, facility—where Trane was founded more than 100 years ago—is helping lead our business into the future with investments and innovation across our broad-based approach to sustainability. We are showing that you can be a growth company, meet your big sustainability commitments and add value to your customers by helping them meet theirs.

“We have to continue focusing on our roots and providing reliability to our customers,” said Tom Gallant, Vice President of Engineering & Technology, Commercial HVAC Americas. “At the same time, we’re trying to find ways to push ourselves and take more risks. I see the team’s mindset shifting every day. We really are a technology company that heats and cools buildings.”

Improving environmental sustainability with innovative technology

The La Crosse team is reducing the environmental impact of our operations through multiple strategies, including renewable energy use, zero waste to landfill and decreasing water use and emissions.

One hundred percent of the electricity used at our La Crosse facility is generated from renewable sources, making it an official RE100 operation. Trane Technologies is a member of RE100, the global renewable energy initiative bringing together businesses committed to using 100% renewable electricity. The La Crosse team achieved this milestone in October 2024 through a five-year power purchase agreement with Xcel Energy.

As of November 2022, the site has achieved zero waste to landfill. The team is diverting industrial waste and scrap material—without disrupting production—to partners who fully recycle the materials or convert combustible items to energy.

The La Crosse facility is Trane Technologies’ largest single user of water for our global operations. Beginning in 2022, a cross-functional team began a multi-year effort to streamline our operations to reclaim and reduce water usage, resulting in a 20 percent reduction in the company’s overall water use in 2023.

In the research and development (R&D) laboratory, water is recycled through a cooling tower, reducing the downtime of the chiller system and reducing water usage by 37 million gallons in 2023 compared to the prior year.

Global Environmental & Sustainability Program Manager Adam Jacobson and VP of Engineering & Technology Tom Gallant talking in front of thermal battery storage source heat pump system

In the training center, we are using our own technology to reduce water use and emissions. There, water is recycled through a thermal battery storage source heat pump system, a first-of-its-kind solution to advance electrified, low-carbon heating in buildings, including in climates below zero degrees Fahrenheit. Commonly referred to as ice storage, the system converges four proven technologies to accelerate building decarbonization: thermal energy storage ice tanks, air-to-water heat pumps, all-electric chiller-heaters and intelligent controls.

The new system saved 15 million gallons of water in 2023—a reduction of 85% from the prior year. The system is estimated to reduce the overall energy intensity of the building by 28%. Going forward, we expect to save 30-40 million gallons of water annually and cut carbon emissions by approximately 21 mtCO2e every year.

Over the last five years, La Crosse’s projects to reduce water use decreased our company’s total water consumption by nearly half.

The La Crosse team continues to find ways to contribute to our Leading by Example commitment, most recently introducing a plan to install geothermal bore field technology to fully electrify heating and cooling of an engineering building on the campus.

Innovating for customers in high-growth sectors

One way we’re innovating for impact in La Crosse is through our developments for high-growth sectors, such as the semiconductor and global data center market, where capacity is projected to nearly double by 2027. Data centers and semiconductor manufacturing require precise cooling and humidity control, so as capacity increases, so will the demand for chillers.

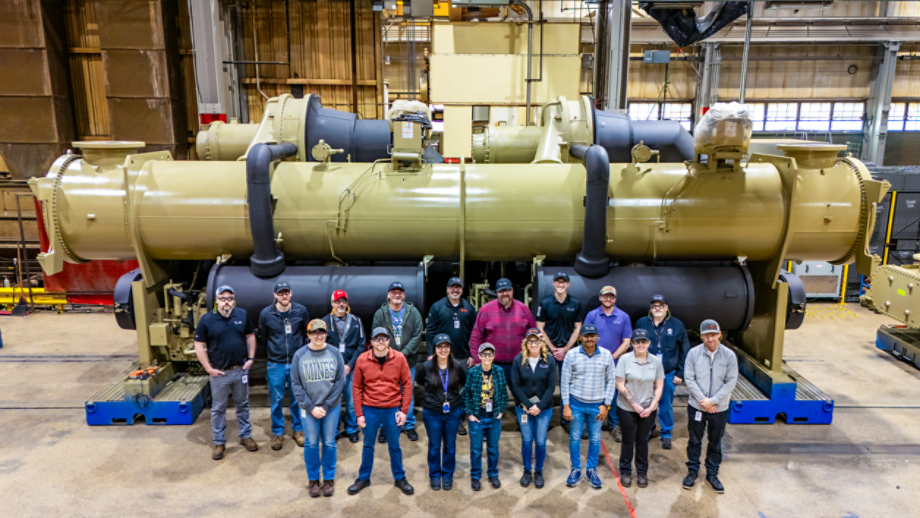

To keep up with this demand, the team in La Crosse built a new manufacturing line for CDHH CenTraVac® water-cooled chillers. This highly automated production line can handle many types of chillers, including our CDHH CenTraVac duplex with heat recovery, which is perfect for buildings with simultaneous heating and cooling load. The heat recovery option captures heat from the condenser, allowing the customer to employ an electrification solution for decarbonization.

Trane CenTraVac chillers offer additional energy-saving options like non-reversible heat pump chiller capabilities, thermal storage down to 20°F (-6.7°C), and integrated free cooling. These features benefit the environment and can often pay for themselves through reduced water consumption, lower heating and ancillary power consumption, and decreased operating costs.

Product Manager Esti Tierney and Plant Manager Shari Werwinski walk the production floor

“We have been serving the high-tech market for a long time, and because of technologies like artificial intelligence, demand is growing,” Tom explained. “What sets us apart is that we make the largest capacity units at the highest efficiency level with a low global warming potential refrigerant.”

Investing in our people through training

Our success is driven by our people. We are creating an inclusive, uplifting culture where people feel they can belong and can boldly share their ideas. We invest in the well-being and career development of our team members so they can thrive.

La Crosse is home to our Graduate Training Program (GTP), a six-month intensive program that develops deep HVAC expertise. With a legacy dating back nearly 100 years, GTP is the foundation of our technical leadership, producing industry-leading account managers and sustainability champions.

Graduate Training Program students in the classroom

We also provide advanced training in welding and other essential skills to support manufacturing excellence. Employees can earn certifications, gain hands-on experience, and advance their careers within Trane Technologies. Additionally, we are expanding a dedicated space for operational and technician training to further develop talent and modernize skills to match the latest technology.

Committed to our community

La Crosse employees are deeply engaged in the community, especially around sharing our expertise in STEM and environmental stewardship. The La Crosse Inclusion Community Network (LINC) leads volunteer initiatives, including STEM education programs at the Boys & Girls Club and the Great River Community Clean-Up, which mobilizes over 120 employees annually. The facility also supports local STEM education, hosting Engineers Week, volunteering with Project Scientist, and sponsoring the Seven Rivers Robotics Regional Competition.

Trane Technologies employee volunteering to help middle schoolers learn about STEM as a part of Engineers Week

Additionally, Trane Technologies contributes to the Trane All Abilities Park, the community’s first inclusive playground, and a new exhibit, coming soon to the La Crosse Children’s Museum, designed to educate children about HVAC technology and innovation.

A legacy of sustainable growth

In La Crosse, and across Trane Technologies, sustainability is not an offshoot of our strategy. It is our strategy and what is driving our growth. The team in La Crosse is continuing to deliver innovative technologies for our customers while reducing the environmental impact of our operations—both by orders of magnitude.

“What makes La Crosse special is that we have multiple generations of families who have worked here,” said Tom Gallant, Vice President of Engineering & Technology, Commercial HVAC Americas. “There is a legacy of innovation we have to live up to every day, and there is so much opportunity. From an engineering standpoint, it’s exciting to work on solving problems that have an impact not only on this community, but our country and the world.”

Topic Tags

English

English